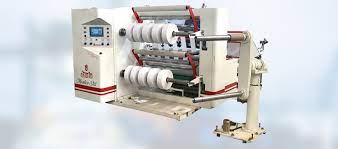

Parthax is a leading manufacturer and supplier of a wide range of printing solutions, including their flagship product, Traverse for Inkjet printer. Based in Noida, India, the manufacturing company has established a reputation for delivering high-quality products that meet the needs of businesses of all sizes.

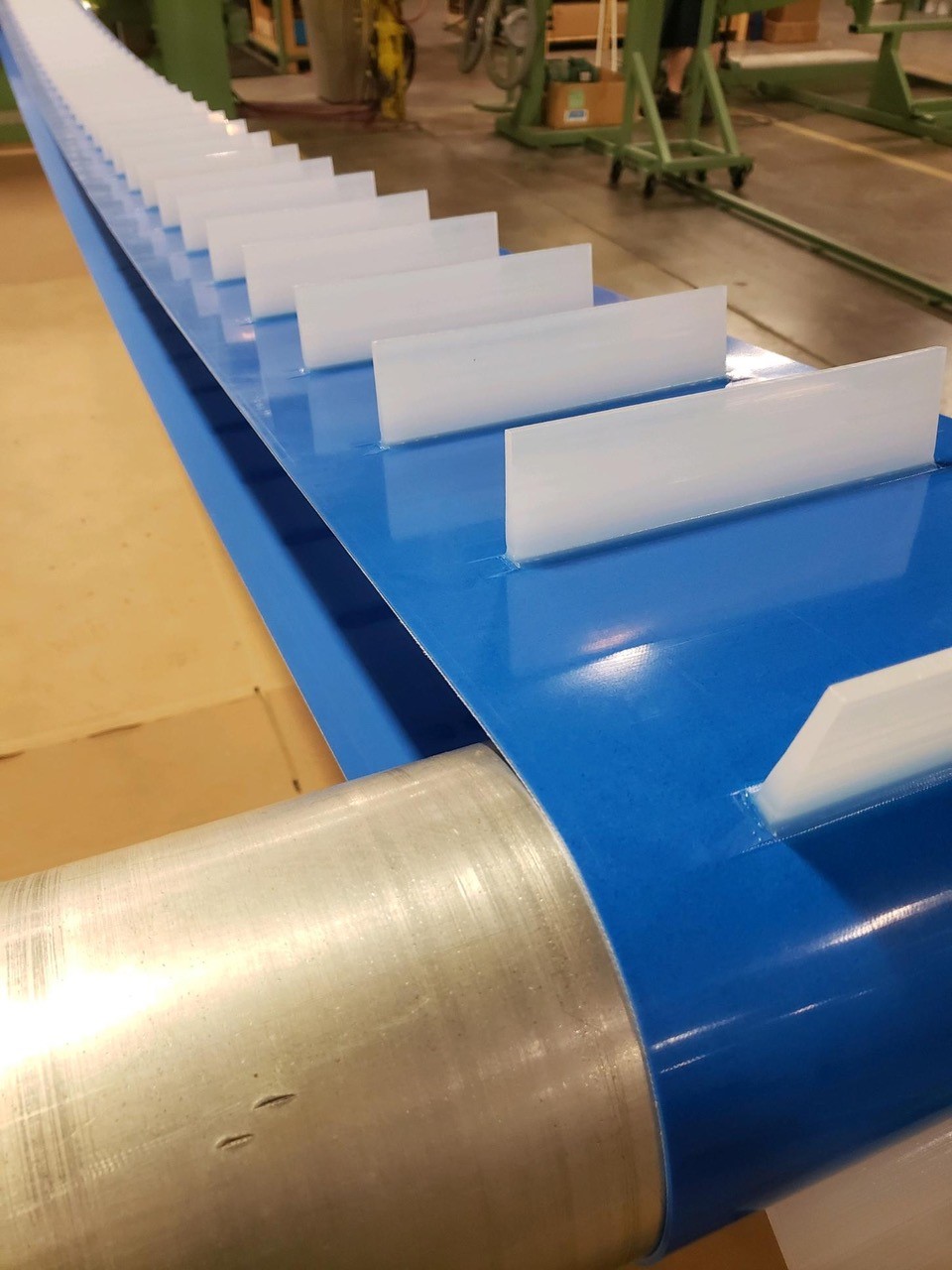

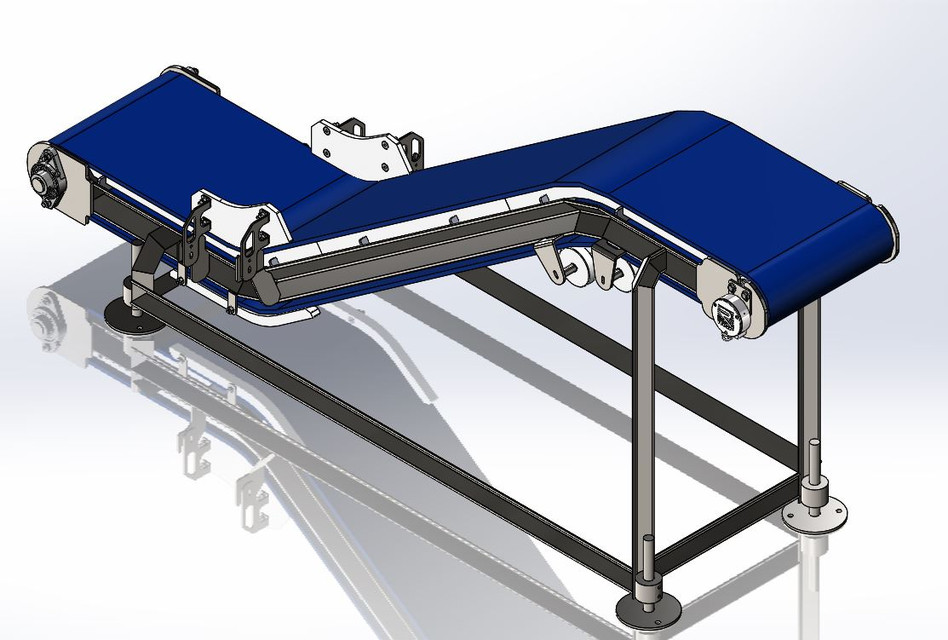

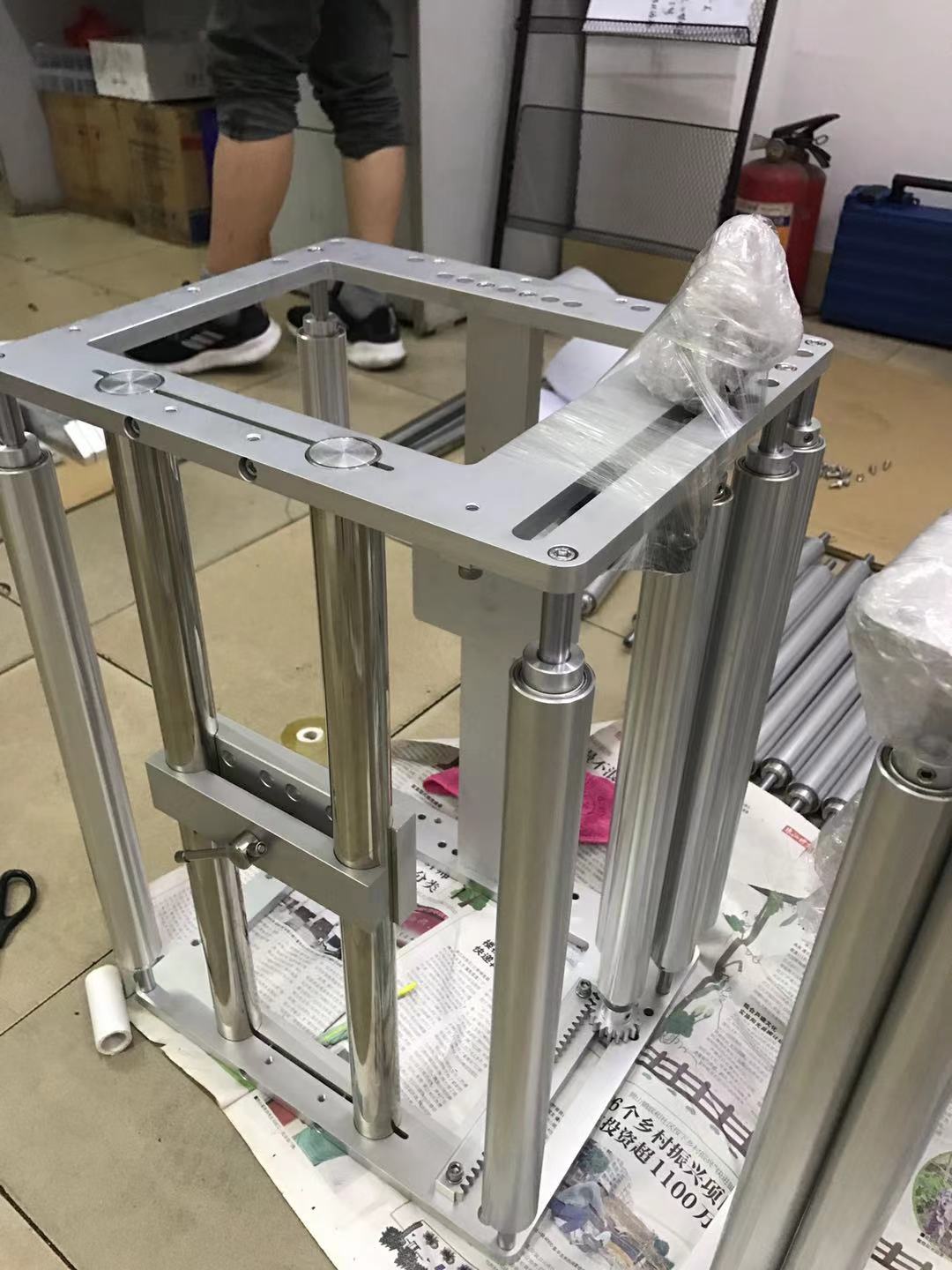

Traverse for Inkjet printer is a versatile and efficient solution designed to meet the needs of businesses that require high-volume printing capabilities. This product is compatible with a wide range of inkjet printers, making it a versatile solution for businesses in a variety of industries.

One of the key advantages of Traverse for Inkjet printer is its ease of use. The product is designed to be user-friendly, with an intuitive interface that makes it easy to set up and use. This means that businesses can start using Traverse for Inkjet printer right away, without the need for extensive training or technical expertise.

In addition to its ease of use, Traverse for Inkjet printer is also known for its reliability. The product is designed to work seamlessly with a range of inkjet printers, ensuring that businesses can rely on it to deliver high-quality results consistently. This is particularly important for businesses that rely on printing for their day-to-day operations, as any downtime or interruptions can have a significant impact on productivity and profitability.

When it comes to prices, Parthax is committed to delivering products that offer exceptional value for money. Despite the high-quality of their products, the manufacturing company strives to keep prices affordable, making their printing solutions accessible to businesses of all sizes. This commitment to affordability has helped Parthax to establish itself as a leading supplier of printing solutions in India and beyond.

Overall, Traverse for Inkjet printer is an excellent choice for businesses that require reliable and efficient printing solutions. Whether you're printing documents, marketing materials, or anything in between, this product is designed to deliver exceptional results, time and time again. And with Parthax's commitment to affordability and exceptional customer service, it's easy to see why they're a top choice for businesses looking for printing solutions that deliver the best possible value.